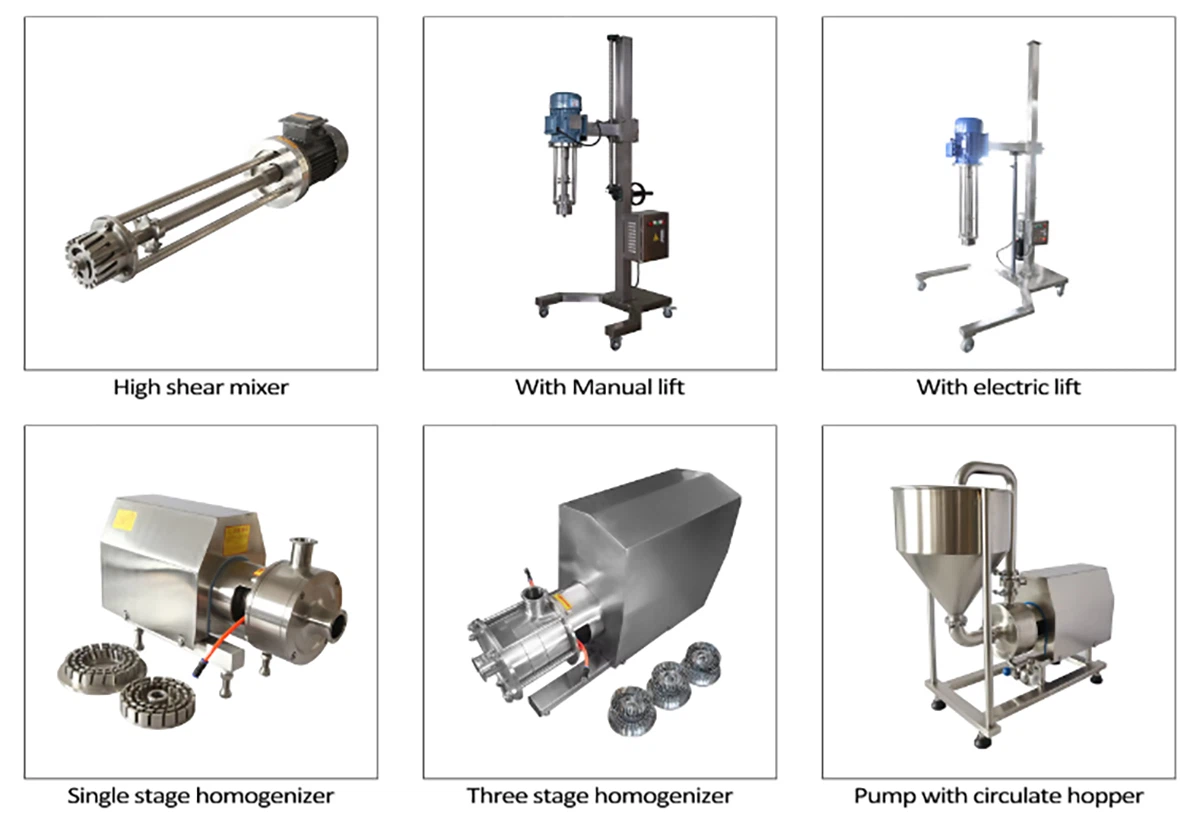

RELATED PRODUCTS

PRODUCT DESCRIPTION

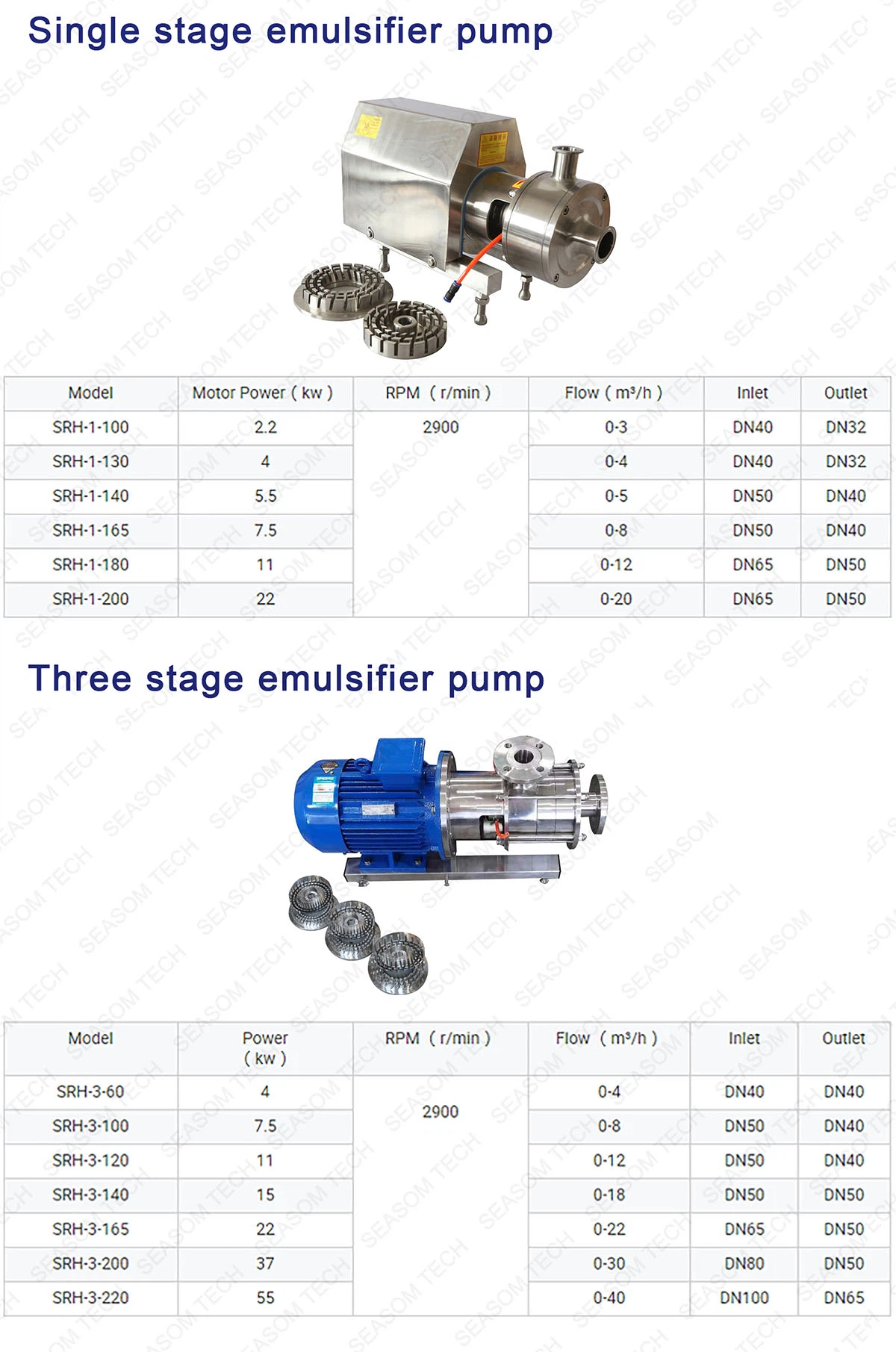

Three-stage emulsifier pumps are highly efficient and versatile machines used in different industries for mixing and blending different substances. As the name suggests, these pumps work through three stages to achieve a homogenous emulsion of the components. Such pumps comprise of high-pressure pumps, mixing chambers, and homogenizing valve units. In this essay, we shall discuss the three-stage emulsifier pump working mechanism, its benefits, and its applications in various industries.

Firstly, the high-pressure pump in the three-stage emulsifier pump system is responsible for forcing the fluid material to the mixing chamber. It operates efficiently at a high rate of flow that allows for the efficient introduction of the materials. The fluid is then passed through the pre-homogenizing valve and the first stage of homogenizing where high pressure is applied. In the first stage, the fluid undergoes the initial homogenization that results in small droplet sizes. This stage provides the foundation for the steady flow of the emulsion, and it also minimizes the stress encountered during the subsequent stages.

Secondly, in the second stage, the fluid is passed through another homogenizing valve unit to achieve further reduction in droplet sizes. This stage significantly helps smoothen the emulsion and also strengthen its consistency. Consequently, it results in fine, uniform, and stable emulsions. The third stage that follows is all about refining the emulsion and enhancing its quality. The fluid is passed through yet another homogenizing valve that achieves the desired droplet size, ensuring that the emulsion remains stable even under harsh conditions.

Three-stage emulsifier pumps offer numerous benefits to various industries. Firstly, they are highly efficient in the production of top-quality emulsions. By creating fine droplets in the first two stages and refining them in the last, these pumps ensure a uniform and stable mixture. Secondly, the pumps are versatile and able to emulsify any material regardless of its viscosity or hardness. This feature makes them suitable for a wide range of industries, including food, cosmetics, and chemical.

Finally, three-stage emulsifier pumps find their application in many fields, including food processing, cosmetics manufacturing, and pharmaceuticals. Food processing industries used them to blend food products and homogenize milk and cheese to create smooth and consistent textures. Cosmetics and pharmaceutical industries utilize these pumps to mix and homogenize oily and water-based solutions to produce creams, lotions, and gels. Additionally, chemical industries use them to mix and emulsify compounds for the production of paints, adhesives, and detergents.

In conclusion, three-stage emulsifier pumps are essential machines utilized in a variety of industries, where they have proven to be dependable, efficient, and effective. Using the first two stages to achieve small droplet sizes and the third stage to refine the emulsion helps to produce high-quality and stable products that meet specific industrial needs. With its broad range of application in various industries, these pumps have become an indispensable part of processes that require the mixing and emulsification of different substances.

DATA SHEET

CERTIFICATE

Send Your Inquiry

Related Products

-

High Shear Mixer with Lifter

A high-shear mixer with a lifter is a powerful processing equipment used extensively in the food, ph...

阅读更多 -

Self Priming Sanitary Pump

A self-priming sanitary pump is a specialized type of pump used in the food, beverage, pharmaceutica...

-

High Shear Dispersion Mixer

High shear dispersion mixer is a type of industrial mixer that is used for mixing and dispersing of ...

-

High Shear Homogenizer Mixer

High shear homogenizer mixer is a tool that is widely used in various industries, including the food...