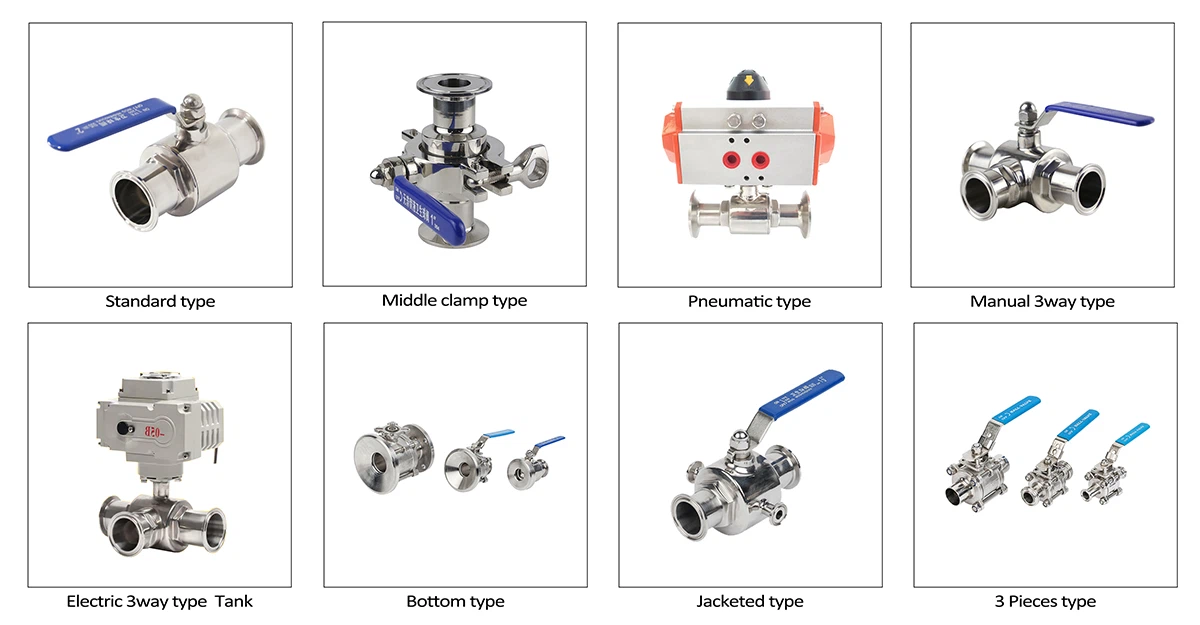

RELATED PRODUCTS

PRODUCT DESCRIPTION

Tank bottom ball valves are crucial components used in the petroleum, oil, and gas industries. They are used to control the flow of fluids such as crude oil, natural gas, and petrochemicals in the tanks they are stored in. The valve is constructed with a spherical ball that has a hole running through the center. The ball is fitted into a valve seat and rotates on an axis to open or close the flow of liquid. This essay will discuss the construction, working principle, and benefits of using a tank bottom ball valve.

Construction of Tank Bottom Ball Valve:

A tank bottom ball valve is typically made of high-quality materials such as stainless steel, carbon steel, or other alloys that can withstand high-pressure and corrosive environments. The valve assembly is composed of a valve body, ball, stem, actuator, and flange. The valve body is primarily designed to connect to the bottom of the storage tank. The ball is held in place by two seats, and the stem connects to the top of the ball and passes through the valve body. The actuator is used to rotate the ball to control fluid flow.

Working principle of tank bottom ball valve:

The working principle of a tank bottom ball valve is relatively simple. When the valve is opened, the ball is rotated by the operator or actuator, which creates a hole along the flow path allowing the liquid to pass through. As the ball turns further, it closes the hole and obstructs the flow of liquid. The ball rotates between two seats, which create a tight seal and prevent liquids from escaping.

Benefits of using a tank bottom ball valve:

The use of tank bottom ball valves offers crucial benefits in the petroleum and petrochemical industries. They are essential for controlling and regulating the flow of fluids, and they can help prevent spills or leaks. These valves provide reliable operation, a tight seal, and minimal leak paths, ensuring the safety and efficiency of the system. Moreover, they reduce maintenance and inspection costs because they require less routine servicing. The valve’s designs also allow easy cleaning and maintenance, improving safety and reducing downtime.

Conclusion:

In conclusion, Tank bottom ball valves are essential components for controlling the flow of fluids in industries such as petroleum, oil, and gas. The valves’ construction with high-quality materials makes it efficient and durable when functioning in adverse environments. The ball seating mechanism and working principle allow for a tight seal on the valve, preventing leaks and spills. The benefits of using tank bottom ball valves include their reliable operation, low maintenance costs, and easy access for cleaning and maintenance. Ultimately, the use of tank bottom ball valves is crucial for ensuring the longevity and efficiency of storage tank systems.

DATA SHEET

| Product Name: | Ball Valve |

| Material: | SS304 Or SS316L |

| Standard: | 3A, SMS, DIN, RS/RJT,ISOIDF,ASME/BPE… |

| Size: | 1/2″-4″,DN15-DN100 |

| Operating Type: | Manual |

| Valve body: | SS304/SS316L |

| Seal Material: | Silicon, EPDM, PTFE |

| Standard: | SMS, DIN, RJT, IDF |

| Packing Details: | Usually bubble pack for each valve within carton box or plywood case, or special packaging upon customer requirements. |

CERTIFICATE

Send Your Inquiry

Related Products

-

Hygienic Penumatic Butterfly Valve With Proximity Sensor

24V DC NPN Inductive proximity sensor C top controller sanitary hygienic penumatic actuator butterfl...

阅读更多 -

3 Way Electric Ball Valve

Electric ball valves are a popular choice in industrial settings due to their convenience and easy o...

-

Union Butterfly Valve

Stainless steel food grade sanitary SMS DIN RJT union butterfly valve

-

3pc Tri Clamp Ball Valve

A 3-piece ball valve is a type of valve that is commonly used in industrial applications. It is also...