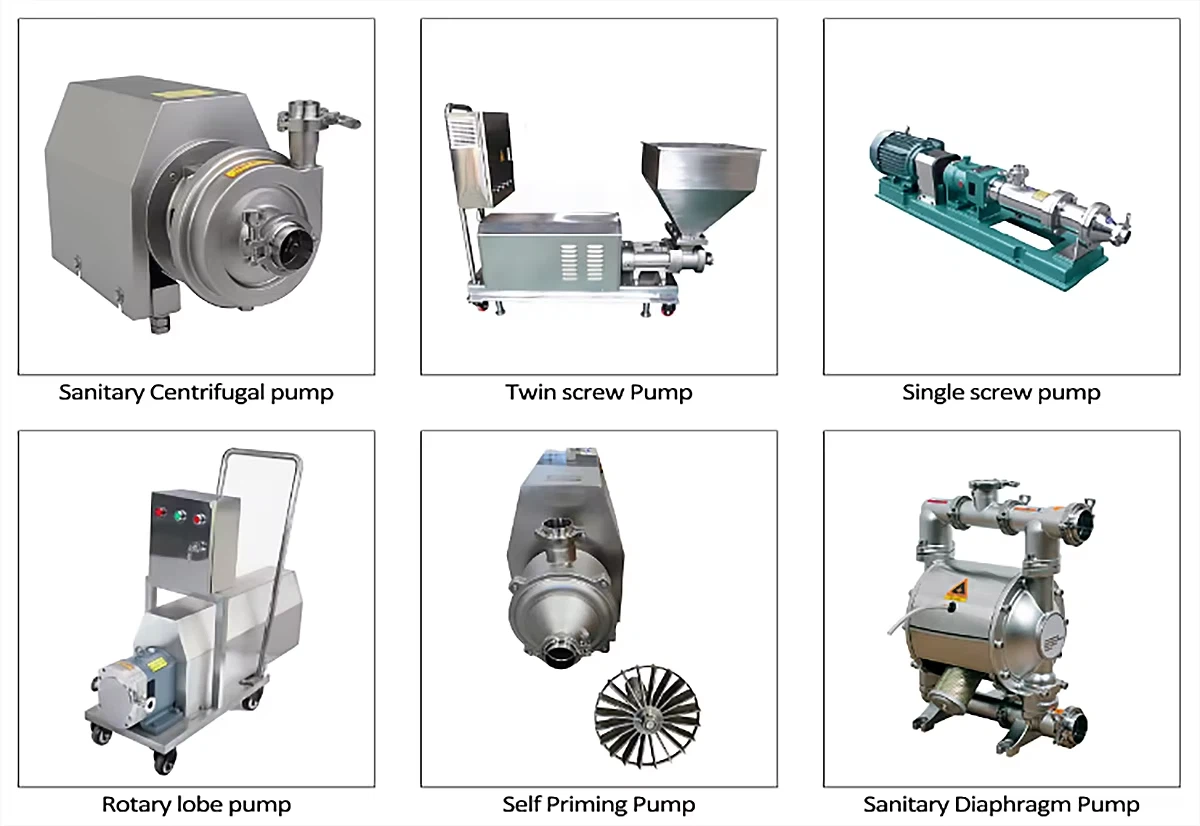

RELATED PRODUCTS

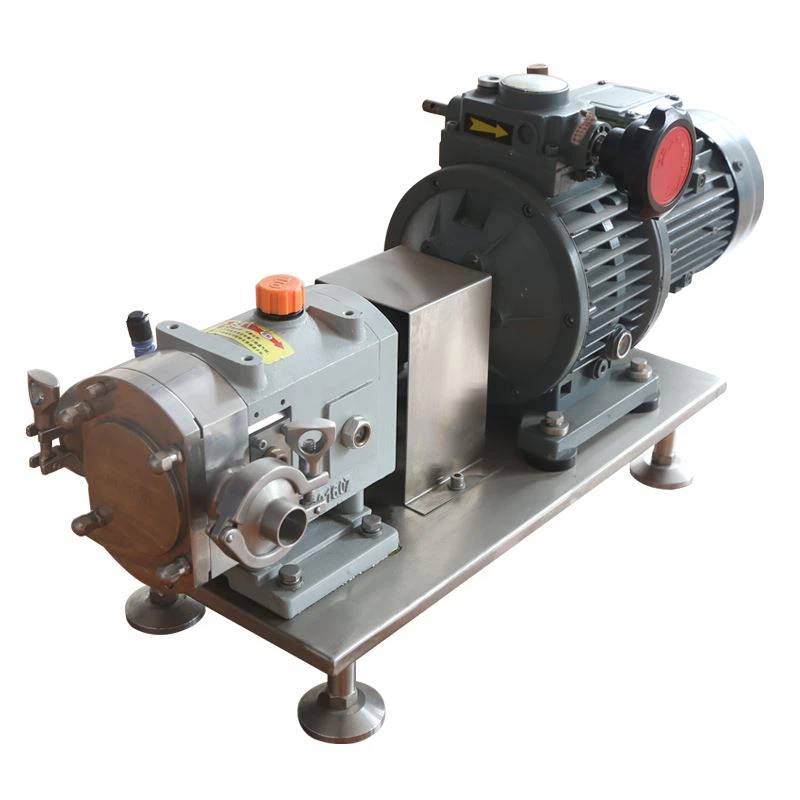

PRODUCT DESCRIPTION

A self-priming sanitary pump is a specialized type of pump used in the food, beverage, pharmaceutical, and cosmetic industries to transfer sensitive or viscous fluids and products. This pump operates on the principle of centrifugal forces to generate a vacuum and prime itself to move the fluid. The self-priming feature eliminates the need for manual priming, making it an efficient and reliable option for processing operations.

Sanitary pumps, in general, conform to high standards of hygienic construction and design to meet the strict health regulations in the industries they operate in. They must be made of materials that are easy to clean and can withstand the corrosive and abrasive nature of the fluids they handle. Cleanability, reliability, and ease of maintenance are essential features that differentiate these pumps from standard industrial pumps.

A self-priming sanitary pump is designed to maintain product integrity by avoiding any contamination of the fluid being transferred. It incorporates a closed impeller that prevents any foreign matter from entering the pump chamber. The impeller is responsible for creating the vacuum that enables the pump to prime itself without the need for an external priming mechanism. In addition, the self-priming feature can help to reduce product waste by eliminating the need to pre-fill the pump before each operation.

In food processing, self-priming sanitary pumps are used for conveying various types of fluids, including those that may be viscous, thick, or have high solid content such as fruit pulps, syrups, sauces, and dairy products. This type of pump can handle products with a wide range of viscosities and densities without causing any damage or compromising their physical properties. Sanitary pumps can also be used for liquid transfer in the cosmetic and pharmaceutical industries, where strict hygiene regulations govern the manufacturing processes.

One of the key benefits of a self-priming sanitary pump is that it increases the efficiency of the fluid transfer process. By eliminating external priming, the pump can reduce the time it takes to start moving the fluid. This feature also reduces the workload of the fluid handlers who do not have to manually prime the pump before each operation. Additionally, self-priming sanitary pumps are highly versatile and can be used in various applications, making them a cost-effective solution for fluid processing operations.

In conclusion, a self-priming sanitary pump is a critical piece of equipment in the food, beverage, cosmetic, and pharmaceutical industries. Its self-priming feature, hygienic design, and ability to handle diverse products make it a preferred choice for fluid transfer applications. The benefits of using a self-priming sanitary pump include increased efficiency, reduced product waste, and improved product integrity. As the need for processing sensitive fluids and products continues to grow, the importance of using reliable, efficient, and hygienic pumping solutions such as self-priming sanitary pumps cannot be overstated.

DATA SHEET

Model | Displacement L / 100RPM | Rotation speed | Corresponding flow rate | Power KW | Pressure | Maximum viscosity | Standard size | Connector form |

YUY-Z-5 | 0.05 | 40-500 | 120-1500 | 0.55-0.75 | 0.1-1.2 | 200000 | Φ25 | Clamp Thread Flange |

YUY-Z-10 | 0.10 | 40-500 | 240-3000 | 1.1-1.5 | 0.1-1.2 | 200000 | Φ32 | |

YUY-Z-15 | 0.15 | 40-500 | 320-4000 | 1.5-2.2 | 0.1-1.2 | 200000 | Φ32 | |

YUY-Z-20 | 0.20 | 40-500 | 480-5400 | 1.5-3 | 0.1-1.2 | 200000 | Φ32 | |

YUY-Z-35 | 0.35 | 40-450 | 840-9450 | 2.2-4 | 0.1-1.2 | 200000 | Φ51 | |

YUY-Z-45 | 0.45 | 40-450 | 950-10500 | 4 | 0.1-1.2 | 200000 | Φ51 | |

YUY-Z-65 | 0.65 | 40-400 | 1560-14000 | 5.5-7.5 | 0.1-1.2 | 200000 | Φ63 | |

YUY-Z-80 | 0.80 | 40-400 | 1750-17000 | 5.5-7.5 | 0.1-1.2 | 200000 | Φ63 | |

YUY-Z-110 | 1.10 | 40-400 | 2400-23500 | 7.5-11 | 0.1-1.2 | 200000 | Φ76 | |

YUY-Z-175 | 1.75 | 40-400 | 3800-37800 | 11-15 | 0.1-1.2 | 200000 | Φ76 | |

YUY-Z-220 | 2.20 | 40-400 | 4750-47500 | 15-18.5 | 0.1-1.2 | 200000 | Φ89 | |

YUY-Z-270 | 2.70 | 40-400 | 5800-58000 | 18.5-22 | 0.1-1.2 | 200000 | Φ89 | |

YUY-Z-365 | 3.65 | 40-400 | 7900-78500 | 22-30 | 0.1-1.2 | 200000 | Φ102 | |

YUY-Z-520 | 5.20 | 40-400 | 11300-110000 | 37-55 | 0.1-1.2 | 200000 | Φ102 |

CERTIFICATE

Send Your Inquiry

Related Products

-

Chocolate Lobe Pump

The chocolate manufacturing industry has seen tremendous growth in the past few years, and with this...

阅读更多 -

High Shear Emulsifier Mixer

A high-shear emulsifier mixer is a complex piece of machinery that has revolutionized the field of f...

-

Sanitary Twin Screw Pump

Sanitary twin screw pumps are widely used in the food, dairy, beverage, and pharmaceutical industrie...

-

High Shear Mixer with Lifter

A high-shear mixer with a lifter is a powerful processing equipment used extensively in the food, ph...