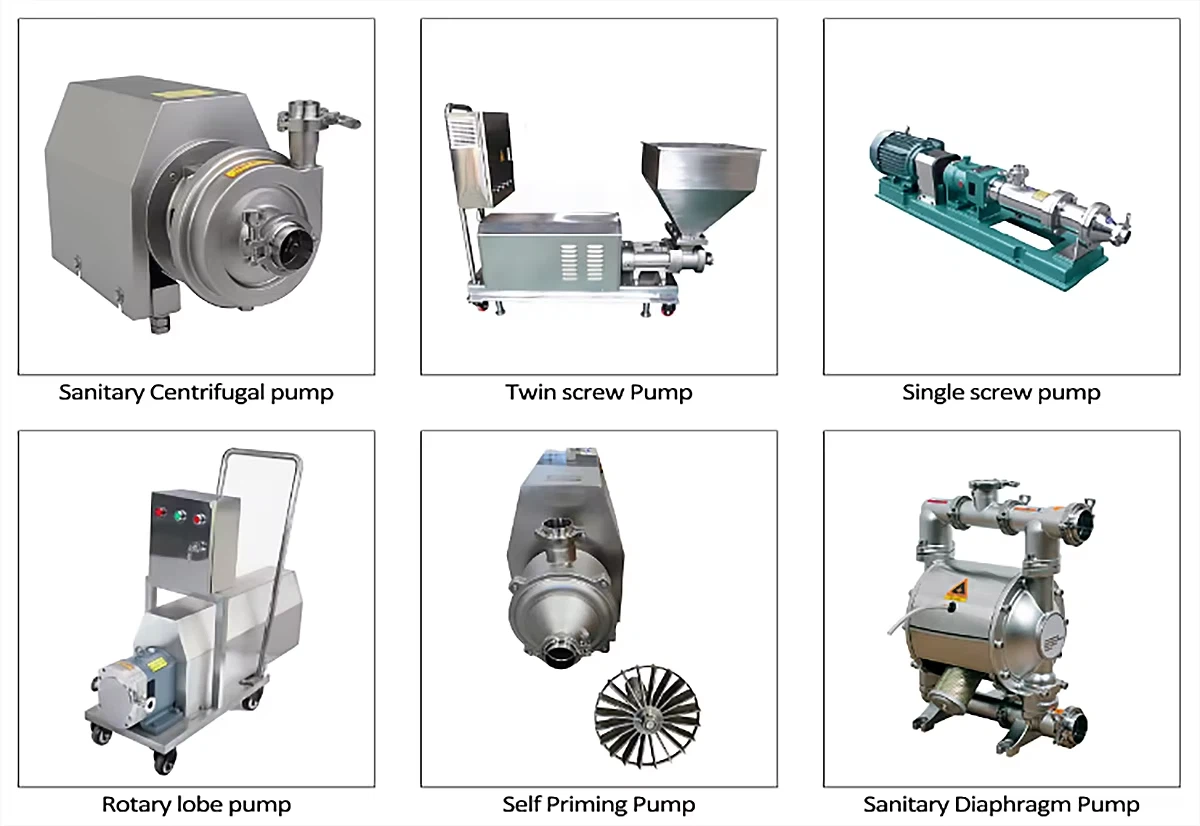

RELATED PRODUCTS

PRODUCT DESCRIPTION

Sanitary twin screw pumps are widely used in the food, dairy, beverage, and pharmaceutical industries for handling viscous and semi-solid materials. These pumps are known for their high efficiency, low pulsation, and gentle handling of sensitive materials. In this essay, we will explore the structure, working principle, and applications of sanitary twin screw pumps.

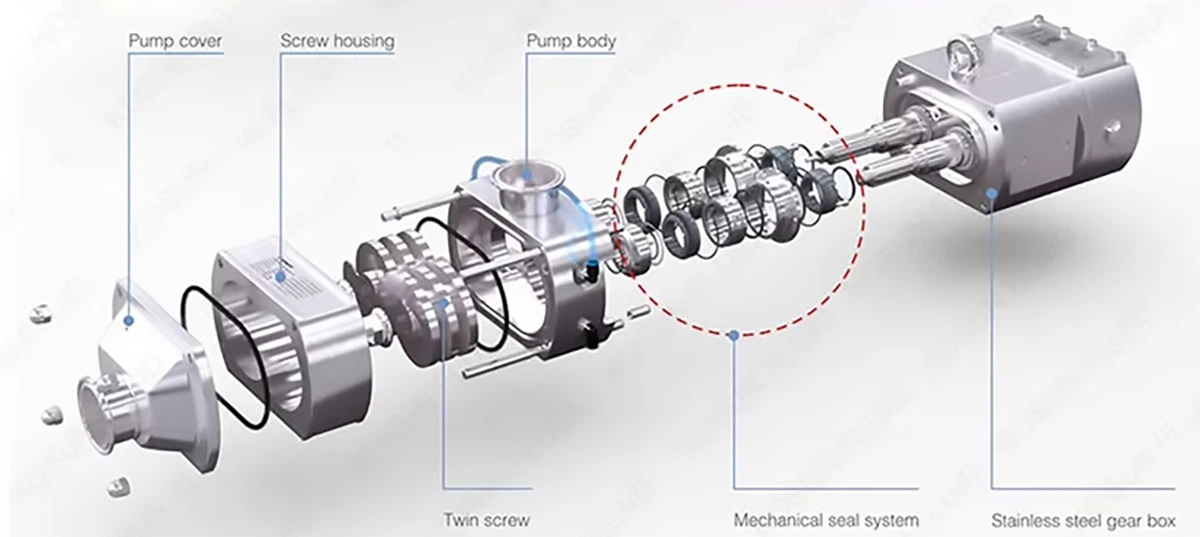

Structure

Sanitary twin screw pumps consist of two screws, a casing, and a seal. The screws are helical in shape and rotate in opposite directions, creating a meshing action that moves the fluid through the pump. The screws are located within a casing that typically has inlet and outlet ports. The seal is located between the casing and the shaft of the pump and prevents any leakage.

Working Principle

The working principle of sanitary twin screw pumps is based on the flow of fluids through the meshing action of the screws. As the screws rotate, the fluid is drawn into the area between the screws and the casing. The meshing of the screws forces the fluid along the screw axis and out the discharge port. This process is continuous and produces a steady flow of fluid through the pump.

Applications

Sanitary twin screw pumps are used in a wide range of applications where viscous or semi-solid materials need to be transported. They are commonly used in food processing for conveying liquids such as dairy products, sauces, and syrups. They are also used in pharmaceutical manufacturing for transferring creams, gels, and ointments.

Sanitary twin screw pumps are particularly useful in applications where sensitive materials need to be transported without degradation or damage. Because of their low pulsation, they are ideal for transferring materials that are prone to foaming or shearing. They are also highly efficient, which makes them an ideal choice for applications that require high volumes of fluid to be transported.

Conclusion

Sanitary twin screw pumps are an efficient and reliable solution for transporting viscous and semi-solid materials in a range of industries. With their high efficiency, low pulsation, and gentle handling of sensitive materials, they are a popular choice for food, dairy, beverage, and pharmaceutical manufacturers. By understanding the structure and working principles of these pumps, businesses can make informed decisions about the most appropriate pumping solutions for their operations.

DATA SHEET

Model | Power (kw) | RPM (r/min) | Flow (m³/h) | Outlet pressure(bar) | Inlet&outlet size(mm) |

TWP-90 | 2.2-4 | 200-2900 | 0-3 | 6-30 | DN50 |

TWP-110 | 5.5-7.5 | 200-2900 | 0-5 | 6-30 | DN65 |

TWP-140 | 11-18.5 | 200-2900 | 0-15 | 6-30 | DN80 |

TWP-160 | 22-30 | 200-2900 | 0-30 | 6-30 | DN80 |

TWP-200 | 37-55 | 200-2900 | 0-50 | 6-30 | DN100 |

CERTIFICATE

Send Your Inquiry

Related Products

-

High Shear Mixer with Lifter

A high-shear mixer with a lifter is a powerful processing equipment used extensively in the food, ph...

阅读更多 -

High Shear Homogenizer Mixer

High shear homogenizer mixer is a tool that is widely used in various industries, including the food...

-

Twin Screw Pump with Hopper

A twin-screw pump with a hopper is a type of positive displacement pump that is commonly used for a ...

-

Stainless Steel Rotary Lobe Pump

Stainless steel rotary lobe pump is a specialized type of equipment that is used to transfer and mov...