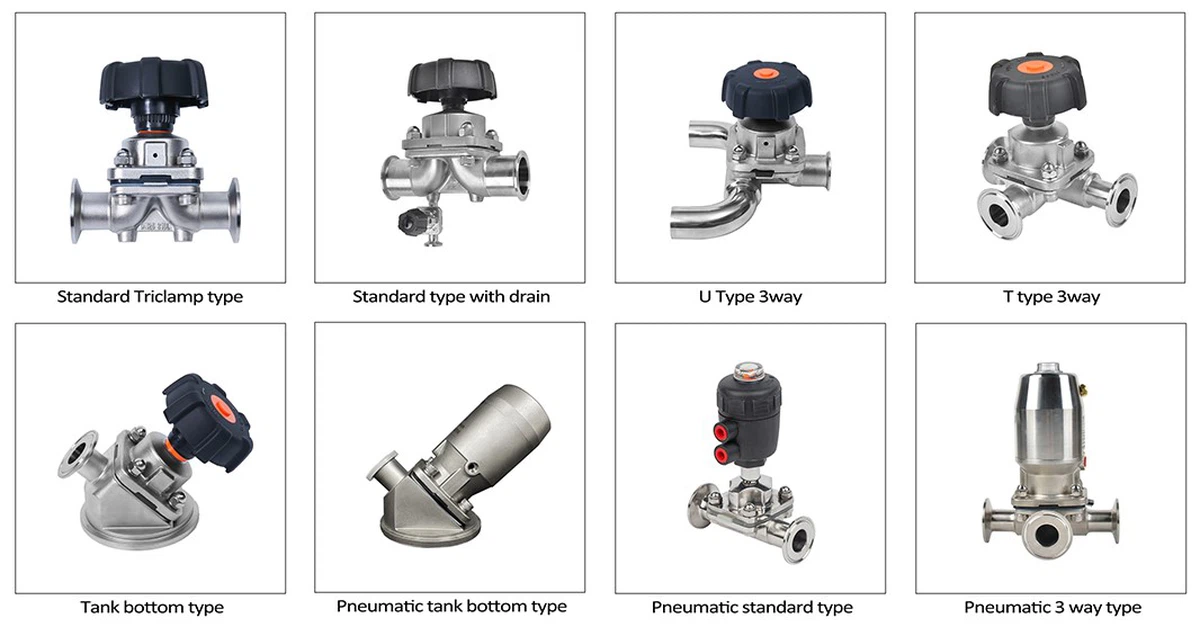

RELATED PRODUCTS

PRODUCT DESCRIPTION

Pneumatic diaphragm valves are a unique type of valve that are known for their versatility and reliability in managing flow control. This type of valve operates using a flexible diaphragm that allows the valve to control the flow of fluid through a pipeline. Pneumatic diaphragm valves are commonly used in many different industries, for tasks such as regulating fluid flow, controlling pressure, and preventing backflow. This essay will elaborate on the properties and applications of pneumatic diaphragm valves in more detail.

Properties

Pneumatic diaphragm valves are comprised of a few key parts that are responsible for its efficient functioning, these being a pneumatic actuator, a metal body, a flexible diaphragm, and a seat ring. The metal body of the valve carries a seat ring on which the flexible diaphragm is clamped. The actuator moves the diaphragm to control flow, which is critical for fluids that are corrosive or contain solids.

One of the main advantages of pneumatic diaphragm valves is that they can be used for a variety of different applications in many different industries. They are known for their ability to handle fluids that have a high viscosity, are corrosive or have abrasive properties. This is because the diaphragm itself can be manufactured in a variety of different materials, including rubber, Viton, EPDM, and PTFE. This flexibility makes them an ideal solution for many different types of fluids.

Applications

Pneumatic diaphragm valves are widely used in the oil and gas industry for various reasons. They are capable of handling fluids that contain solids such as mud, sand, and clay. Furthermore, these valves can be employed under high-pressure conditions, where other valves are not able to function effectively.

One of the most widespread applications of pneumatic diaphragm valves is for controlling flow inside a pipeline. The valve functions to regulate the flow of fluids according to the pressure that the valve is controlled with. Pneumatic diaphragm valves are also used in the food and beverage industry where they are employed for clean-in-place or sterilisation processes. One of the advantages of using these types of valves is that they typically require less maintenance when compared to other valves.

In addition, pneumatic diaphragm valves are frequently used to regulate water treatment processes. They are ideal for these applications where a high degree of control over flow is necessary. They are commonly chosen as an option to regulate flow within water chlorination systems, pump systems, and effluent treatment plants.

Conclusion

In conclusion, pneumatic diaphragm valves are a type of valve that has several advantageous properties, making them an ideal solution for various industrial applications. Pneumatic diaphragm valves are durable, reliable, and capable of handling a variety of different fluids. They also enable precise control over flow, contributing to efficient and effective operations. By understanding its properties and application, it is clear that pneumatic diaphragm valves have an important role in many different industries.

DATA SHEET

Product Name: | Sanitary Diaphragm Valve |

Material: | SS316L |

Standard: | 3A, SMS, DIN, RS/RJT, ISO/IDF,ASME/BPE… |

Size: | 1/2″ -4″ , DN15-DN100 |

Operating Type: | Manual Pneumatic Electric |

Valve body: | SS316L |

Seal Material: | Silicon, EPDM, PTFE |

Standard: | SMS, DIN, RJT, IDF |

Packing Details: | Usually bubble pack for each valve within carton box or plywood case, or special packaging upon customer requirements. |

CERTIFICATE

Send Your Inquiry

Related Products

-

Screw Check Valve

The screw check valve is an efficient and reliable fluid control valve that prevents fluid backflow ...

阅读更多 -

2 Piece Ball Valve

A 2-piece ball valve is a type of valve that uses a rotating ball with a hole to control the flow of...

-

Flange Ball Valve

Flange ball valves are an essential component in pipelines used to transport liquids, gases, and oth...

-

3pc Ball Valve

A 3-piece ball valve is a type of valve that is widely used in various industrial applications. It h...