RELATED PRODUCTS

PRODUCT DESCRIPTION

As the name suggests, a liquid powder mixer is a specialized machine designed to blend liquid and powder into a consistent and homogenous mixture. The device has wide applications in various industries, such as food, pharmaceuticals, cosmetics, and chemical processing. These machines are highly efficient, productive, and reliable, thus offering many advantages to industries that use them.

The liquid powder mixer operates through a mechanism that consists of a mixing chamber, mixing blades, and motors. The liquid flows into the chamber first, followed by powders that are fed through a hopper. The mixer blades then rotate evenly to create a consistent vortex that pulls the liquid and powder mixture into the center and around the blades. The resulting mixture is then discharged through a valve or nozzle.

One of the most significant benefits of liquid powder mixers is that they can achieve extremely high mixing accuracy, with the ability to produce a homogeneous mixture with micro-scale particles. In the food industry, this means that the ingredients for a cake can be mixed to form a consistent batter with the same texture and viscosity every time, regardless of the batch size. The machine ensures that no lumps or air pockets form in the mixture, which is crucial in the production of many products.

Another advantage of liquid powder mixers is their ability to handle a wide range of materials, both liquid and powder. The device can be used to mix dry powders, liquid solutions, and even highly viscous materials, such as pastes and gels. It can also process materials with varying particle sizes and densities.

Furthermore, liquid powder mixers offer excellent process control in terms of temperature, flow rate, and mixing time. This makes the system ideal for products that have specific requirements, such as heat-sensitive products that cannot be overheated during mixing. The machine’s ability to control temperature during production ensures that the product’s quality is maintained, and that the output is consistent every time.

In conclusion, liquid powder mixers are essential machines for many industries, offering benefits such as high mixing accuracy, the ability to handle a wide range of materials, and excellent process control. The machine’s advanced technology ensures that the final product is of high quality, consistent, and free from lumps and air pockets. Industries that use liquid powder mixers save time, reduce costs, and can produce a variety of products with great efficiency. The use of liquid powder mixers is, therefore, highly recommended for any industry that requires a high level of mixing accuracy, consistency, and reliability.

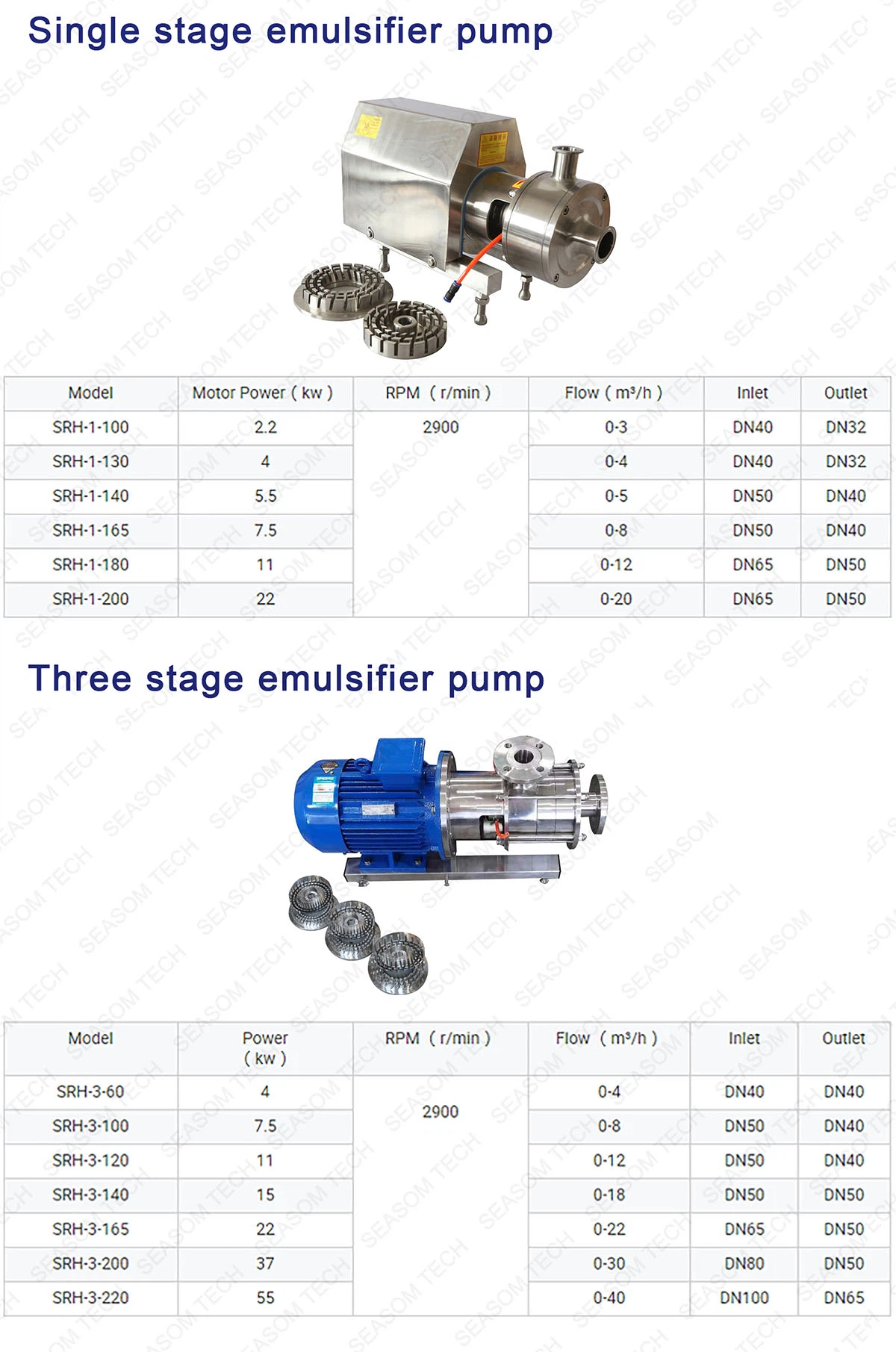

DATA SHEET

CERTIFICATE

Send Your Inquiry

Related Products

-

High Shear Homogenizer Mixer

High shear homogenizer mixer is a tool that is widely used in various industries, including the food...

阅读更多 -

High Shear Dispersion Mixer

High shear dispersion mixer is a type of industrial mixer that is used for mixing and dispersing of ...

-

High Shear Inline Mixer with Hopper

A high-shear inline mixer with hopper is a versatile and efficient piece of equipment that is used a...

-

Stainless Steel Rotary Lobe Pump

Stainless steel rotary lobe pump is a specialized type of equipment that is used to transfer and mov...