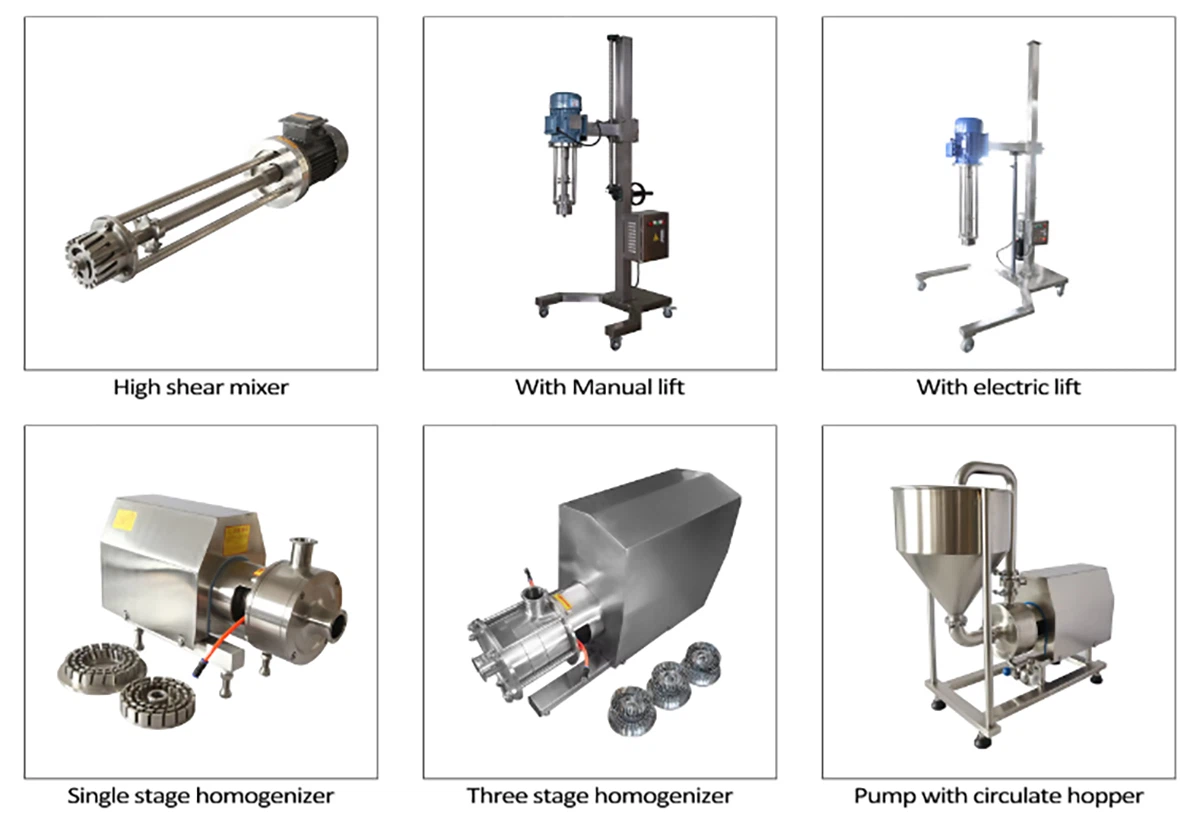

RELATED PRODUCTS

PRODUCT DESCRIPTION

A high-shear mixer with a lifter is a powerful processing equipment used extensively in the food, pharmaceutical, and chemical industries. The mixer facilitates the production of homogeneous and consistent mixes, reduces processing time, and enhances quality control. In this essay, we will discuss the working principle, benefits, and applications of high-shear mixers with lifters.

A high-shear mixer, as the name implies, uses high-shear forces to blend materials into a homogeneous mix. This is achieved by rotating a specially-designed impeller at a high speed, which creates a powerful vortex in the mixing vessel. The impeller is typically designed with sharp blades arranged in a helical pattern, which cuts through the materials and disperses them uniformly.

While high-shear mixers work exceptionally well, they have one major limitation: the materials need to be in a liquid form. This is where the lifter comes in. In a high-shear mixer with a lifter, the materials are first loaded into the mixing vessel, which is then raised to a predetermined height. This allows the materials to become more fluid and easier to mix while also protecting the mixer’s impeller from damage.

One significant advantage of high-shear mixers with lifters is that they can process larger batches of materials. The lifter allows for a greater volume of materials to be loaded into the mixer, and the high-shear forces ensure that the entire batch is mixed uniformly, regardless of its size. This results in a more consistent product while also improving production efficiency.

Another significant benefit of high-shear mixers with lifters is the ability to control the mixing process more precisely. The height of the lifter can be adjusted to control the mixing intensity, which allows for a greater degree of control over the final product’s quality and consistency. Additionally, the mixer can be operated at a lower speed, which reduces the likelihood of materials splashing out of the vessel.

High-shear mixers with lifters are used in a wide range of industries, including food, pharmaceuticals, and chemicals. In the food industry, they are used to mix dough, sauces, and various other ingredients. They are also used in the pharmaceutical industry to prepare suspensions, emulsions, and other products. In the chemical industry, high-shear mixers with lifters are used to blend chemicals and pigments, among other applications.

In conclusion, high-shear mixers with lifters are powerful processing equipment that is widely used in many industries. The mixer’s ability to create consistent and homogeneous blends quickly and efficiently can significantly improve production efficiency while also improving product quality. The versatility and precision of high-shear mixers with lifters make them an essential tool in the manufacturing process for many different products.

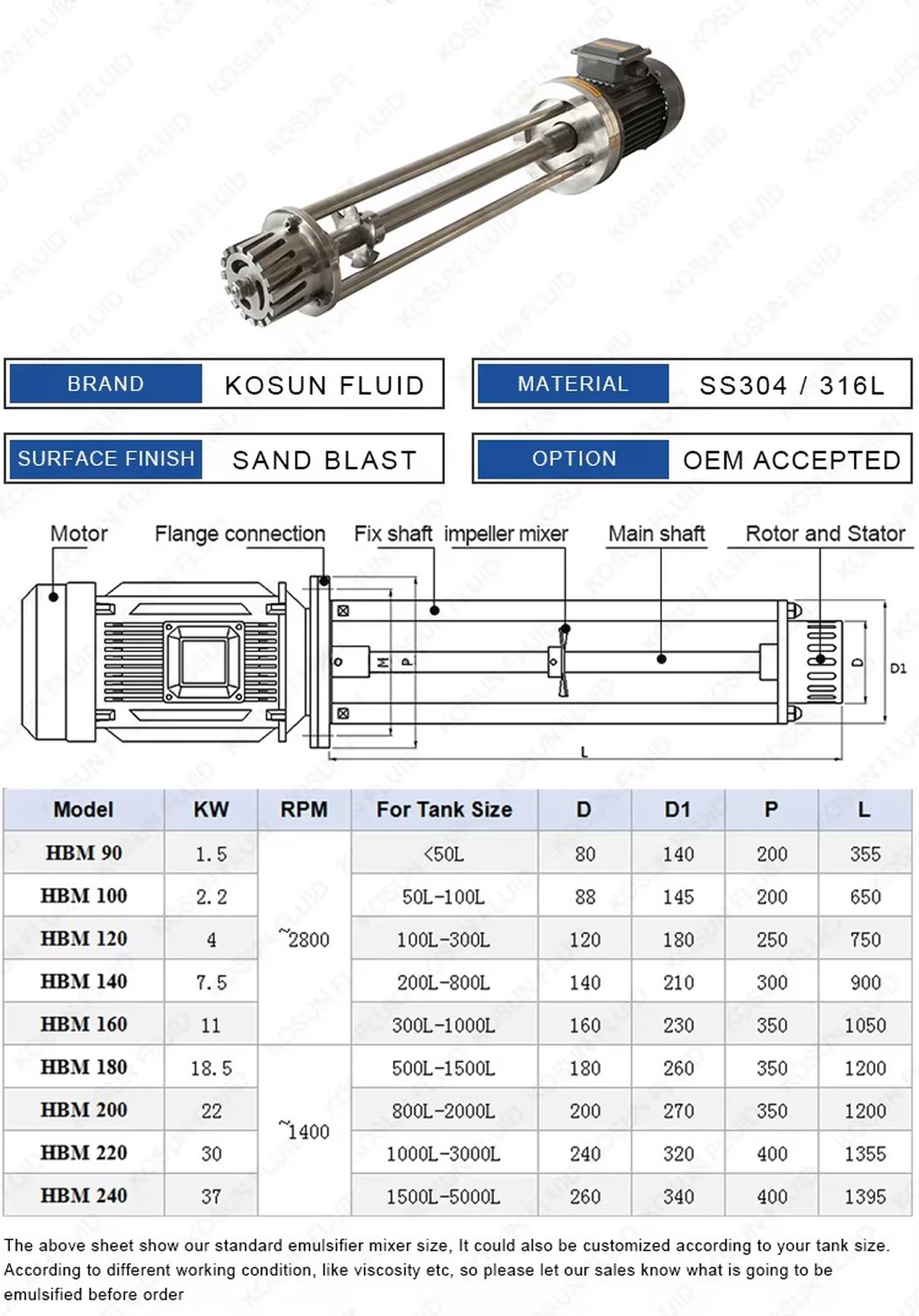

DATA SHEET

CERTIFICATE

Send Your Inquiry

Related Products

-

Three Stage Emulsifier Pump

Three-stage emulsifier pumps are highly efficient and versatile machines used in different industrie...

阅读更多 -

High Shear Dispersion Mixer

High shear dispersion mixer is a type of industrial mixer that is used for mixing and dispersing of ...

-

Chocolate Lobe Pump

The chocolate manufacturing industry has seen tremendous growth in the past few years, and with this...

-

High Shear Inline Mixer with Hopper

A high-shear inline mixer with hopper is a versatile and efficient piece of equipment that is used a...