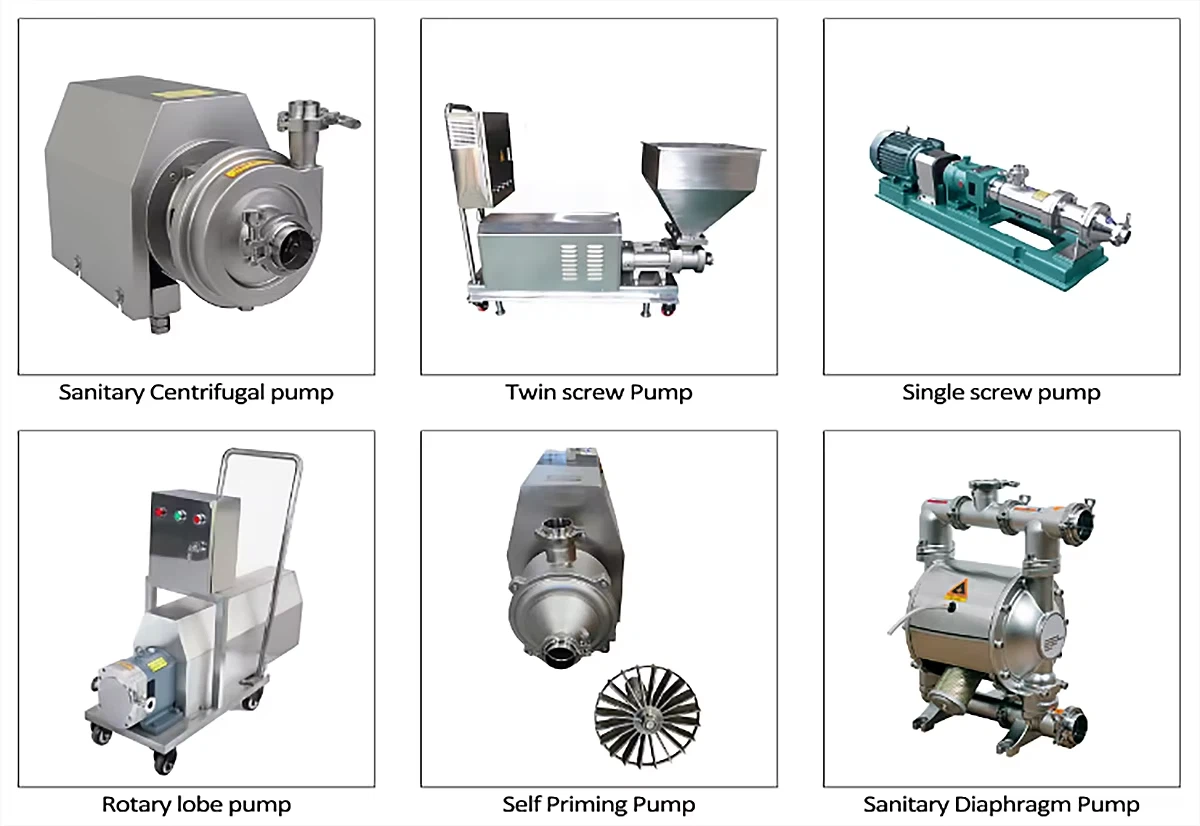

RELATED PRODUCTS

PRODUCT DESCRIPTION

CIP (Clean-in-Place) pumps are an essential component in the food and beverage industry. These pumps are used to clean and sterilize processing equipment such as tanks, pipelines, and other machinery. CIP pumps are designed specifically for the cleaning process, which eliminates the need for disassembling machinery and cleaning manually. This essay will cover the importance of CIP pumps, their functions, and the different types of CIP pumps available in the market.

CIP pumps are essential components of the cleaning process within the food and beverage industry as they provide an efficient and cost-effective solution for cleaning and sterilizing equipment. In the past, cleaning and sanitation was done manually, which was a lengthy and labor-intensive process. With the advancement of technology, the introduction of CIP pumps has revolutionized the cleaning process. CIP pumps are designed to clean and sanitize processing equipment with minimal human intervention, which improves efficiency and reduces production downtime.

The main function of a CIP pump is to propel the cleaning solution through the processing equipment, breaking down any residues and contaminants and removing them from the equipment’s surface. The CIP system uses a combination of cleaning agents and water, which is heated to a high temperature to provide an effective cleaning solution. The cleaning agent varies depending on the type of equipment and the substances being removed, but the most commonly used cleaning agents are alkaline, acid, and disinfectants.

There are different types of CIP pumps available in the market, with the most common ones being centrifugal and positive displacement pumps. Centrifugal pumps are widely used in the food and beverage industry due to their high flow rate capabilities and low maintenance requirements. Positive displacement pumps, on the other hand, are used for high viscosity fluids such as creams, syrups, and sauces. They are also used to pump small volumes of fluid at a high pressure.

CIP pumps are an essential component of the cleaning process, and their importance cannot be overstated. They improve hygiene standards and reduce the risk of contamination, which also impacts the quality and freshness of the final products. CIP pumps also reduce the amount of water and cleaning agents used, which is environmentally friendly and reduces operational costs. Therefore, it is essential for processing industries to invest in CIP pumps for efficient and cost-effective cleaning within their facilities.

In conclusion, CIP pumps are essential components in the food and beverage industry, and their importance cannot be underestimated. They provide an efficient and cost-effective solution for cleaning and sanitizing processing equipment, which improves hygiene standards and reduces the risk of contamination. The different types of CIP pumps available, including centrifugal and positive displacement pumps, offer solutions for different types of equipment and substances being removed. Ultimately, investing in CIP pumps is beneficial for processing industries, as it reduces operational costs and improves product quality.

DATA SHEET

Model | Displacement L / 100RPM | Rotation speed | Corresponding flow rate | Power KW | Pressure | Maximum viscosity | Standard size | Connector form |

YUY-Z-5 | 0.05 | 40-500 | 120-1500 | 0.55-0.75 | 0.1-1.2 | 200000 | Φ25 | Clamp Thread Flange |

YUY-Z-10 | 0.10 | 40-500 | 240-3000 | 1.1-1.5 | 0.1-1.2 | 200000 | Φ32 | |

YUY-Z-15 | 0.15 | 40-500 | 320-4000 | 1.5-2.2 | 0.1-1.2 | 200000 | Φ32 | |

YUY-Z-20 | 0.20 | 40-500 | 480-5400 | 1.5-3 | 0.1-1.2 | 200000 | Φ32 | |

YUY-Z-35 | 0.35 | 40-450 | 840-9450 | 2.2-4 | 0.1-1.2 | 200000 | Φ51 | |

YUY-Z-45 | 0.45 | 40-450 | 950-10500 | 4 | 0.1-1.2 | 200000 | Φ51 | |

YUY-Z-65 | 0.65 | 40-400 | 1560-14000 | 5.5-7.5 | 0.1-1.2 | 200000 | Φ63 | |

YUY-Z-80 | 0.80 | 40-400 | 1750-17000 | 5.5-7.5 | 0.1-1.2 | 200000 | Φ63 | |

YUY-Z-110 | 1.10 | 40-400 | 2400-23500 | 7.5-11 | 0.1-1.2 | 200000 | Φ76 | |

YUY-Z-175 | 1.75 | 40-400 | 3800-37800 | 11-15 | 0.1-1.2 | 200000 | Φ76 | |

YUY-Z-220 | 2.20 | 40-400 | 4750-47500 | 15-18.5 | 0.1-1.2 | 200000 | Φ89 | |

YUY-Z-270 | 2.70 | 40-400 | 5800-58000 | 18.5-22 | 0.1-1.2 | 200000 | Φ89 | |

YUY-Z-365 | 3.65 | 40-400 | 7900-78500 | 22-30 | 0.1-1.2 | 200000 | Φ102 | |

YUY-Z-520 | 5.20 | 40-400 | 11300-110000 | 37-55 | 0.1-1.2 | 200000 | Φ102 |

CERTIFICATE

Send Your Inquiry

Related Products

-

Stainless Steel Rotary Lobe Pump

Stainless steel rotary lobe pump is a specialized type of equipment that is used to transfer and mov...

阅读更多 -

High Shear Inline Mixer with Hopper

A high-shear inline mixer with hopper is a versatile and efficient piece of equipment that is used a...

-

Sanitary Twin Screw Pump

Sanitary twin screw pumps are widely used in the food, dairy, beverage, and pharmaceutical industrie...

-

Liquid Powder Mixer

As the name suggests, a liquid powder mixer is a specialized machine designed to blend liquid and po...