Tri Clamp Butterfly Valve

Triclamp butterfly valves are an essential component in the industrial manufacturing process. These ...

阅读更多

Tri Clamp Diaphragm Valve

A diaphragm valve is a type of valve that uses a flexible diaphragm to separate the flow of liquid o...

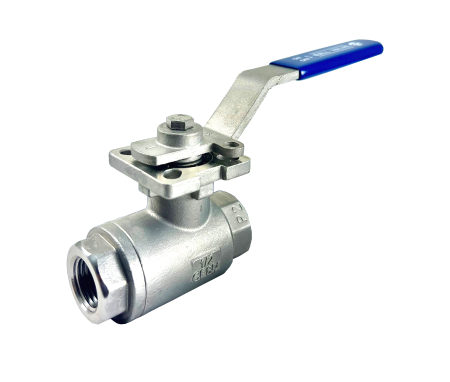

Tri Clamp Electric Ball Valve

Triclamp electric ball valve is a type of valve that is used to regulate the flow of fluids in a pip...

Tri Clamp Food Grade Check Valve

Triclamp Food Grade Check Valve is an essential component of the food and beverage industry. The val...

Tri Clamp Pressure Relief Safety Valve

1.5″ tri clamp stainless steel pressure relief safety valve

Tri Clamp Safety Valve

Triclamps have been widely used in various industries for the purpose of joining two pipes or tubing...

Tri Clamp Sampling Valves

Tri-clamp sampling valves refer to a type of valve designed for use in the pharmaceutical, chemical,...

Union Butterfly Valve

Stainless steel food grade sanitary SMS DIN RJT union butterfly valve