Pumps and mixers are essential equipment used to transport, circulate, and blend liquids or semi-fluids in industrial processes. Pumps provide stable and efficient fluid transfer, while mixers ensure uniform mixing of materials to achieve consistent product quality. They are widely used in chemical, food, pharmaceutical, and wastewater treatment industries, offering reliable performance, energy efficiency, and long service life.

Xingsheng Mechanical Technology Co., Ltd is located in Wenzhou city, Southeast coast of China. It is established in the year 2005, with a registered capital of 50 million RMB. In the year 2022 Xingsheng has over 150 staff, 10000 square meters of workshop, and over 20 million (USD) annual turnover.

During continuous effort over the past 15 years, Xingsheng has acquired IS0:9001, ISO:14001, and ISO45001 certifications. And 3A certificate for food-grade pipe fitting in the year 2022.

We have a variety of products. Our main product includes all kinds of forged stainless steel flanges, Stainless steel valves, and Stainless steel pipe fittings for both food-grade and industrial applications.

Xingsheng has more than 10 years of export experience, our main export markets include the United States, South America, Australia, Southeast Asia and Europe. Based on our strict quality control system and quality products. We have exported more and more products worldwide.

With Mature technology and good supporting services, dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. OEM and ODM service is welcomed!

Sight glass manways are specialized components used in industrial equipment, particularly in tanks and vessels, to provide a visual inspection of the interior without the need for opening the container. These manways incorporate a sight glass or transparent window, allowing operators to observe processes, levels, and conditions inside the tank or vessel.

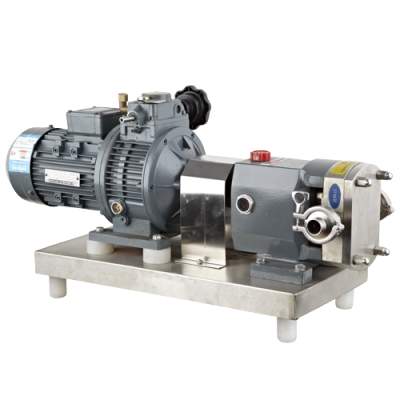

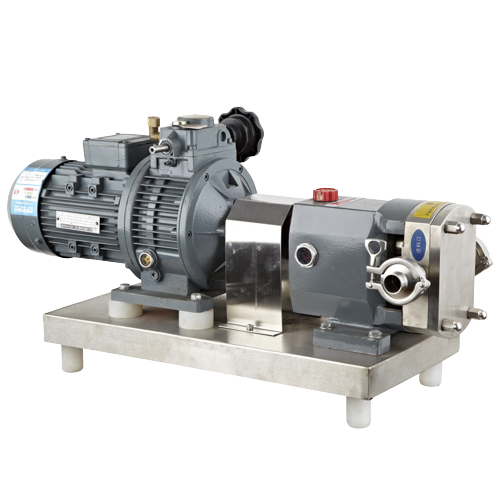

Pumps and mixers feature high efficiency, stable performance, and durable construction for long-term industrial use. They offer precise flow and speed control, low noise operation, and easy maintenance. With corrosion-resistant materials and advanced sealing systems, they ensure safe, reliable operation and consistent mixing or fluid transfer in demanding working environments.

Drive Mechanism: Pumps can be driven by electric motors, engines, or other power sources.

Sealing Mechanism: Equipped with sealing mechanisms to prevent leakage.

Materials of Construction: Constructed from materials compatible with the pumped fluid.

Pressure Ratings: Designed to handle specific pressure conditions.

Temperature Ratings: Capable of operating within specified temperature ranges.

Maintenance Requirements: Varying maintenance needs depending on pump type.

Shear Mixing: Involves forces that shear or break down particles for thorough mixing.

Blend Mixing: Gentle mixing process where substances are combined for a uniform mixture.

Homogenization: Achieves homogeneity in the mixture through efficient blending.

Electric or Mechanical Drive: Mixers can be powered by electric motors or mechanical systems.

Variable Speed Control: Some mixers allow variable speed control for flexibility in mixing intensity.

Compatibility: Constructed from materials compatible with the mixed substances.

Sanitary Design: Mixers used in industries like food and pharmaceuticals may have sanitary designs.

Ease of Cleaning: Designed for easy cleaning to prevent cross-contamination.

Wear Resistance: Components may be designed for wear resistance to prolong equipment life.

Overload Protection: Some mixers come with overload protection mechanisms for safety.

Emergency Stop: Equipped with emergency stop features for quick cessation of operations.

Pumps play a crucial role in ensuring the efficient transfer of fluids within industrial processes, providing the necessary pressure to move liquids or gases through pipelines.

Pumps can help to increase the efficiency of a system by reducing the amount of energy required to move fluids.

Pumps can be used to move dangerous or toxic fluids, reducing the risk of exposure to workers.

Pumps can help to increase productivity by allowing fluids to be moved quickly and efficiently.

Pumps can help to reduce costs by reducing the amount of waste and minimizing the need for manual labor.

Pumps are widely used in industrial and commercial applications to transfer and circulate liquids efficiently. They are commonly applied in water treatment, chemical processing, oil and gas, food and beverage production, power plants, and HVAC systems. Pumps help maintain stable flow, pressure control, and continuous operation, ensuring safe, reliable, and energy-efficient fluid handling in various working environments.

Oil and Gas upstream, midstream and downstream applications all utilize different pumps in unique ways to tackle the challenges of the industry.

Pumps serve a vital role in the agricultural industry by transferring water to livestock and supplying irrigation to crops and small villages.

The mining industry employs pumps for a myriad of applications including tailings reclamation or removal, slurry transfer, and mine dewatering processes.

Paper and pulp mills depend on multiple types of pumps to move caustic and abrasive chemicals to different processes during the manufacturing process.

Heavy duty solids handling pumps are typically used in dredge systems, allowing the operator to work without the fear of clogs or downtime to the operation.

Dewatering can be performed by multiple types of pumps for removing water from multiple situations for flood control, wellpoints, bypass and other applications.

From sewage transfer, wastewater treatment, to clean water purification systems, municipalities rely on the power of pumps to drive these complex systems.

The flow you require: generally measured in m3/h (cubic meters per hour) or GPM (gallons per minute), the flow necessarily influences the size and dimensions of your pump;

The suction head (height between the inlet of the suction pipe and the pump): as a general rule, the suction head must not exceed 10 meters. Beyond this, it is necessary to consider using a submersible pump.

The discharge head (height between the pump and the discharge pipe outlet).

The length of the discharge circuit.

Head losses linked to obstacles on the pumping circuit (valves, bends, etc.).

Whether there is a discharge tank or not could change the head.

The temperature thus depends on the choice of pump casing

One of the primary advantages of buying a new industrial mixer is the assurance of reliability and optimal performance. With a new mixer, you can trust that it hasn’t undergone wear and tear or been subjected to previous heavy usage. This means you can expect consistent and efficient operation, resulting in higher productivity for your business.

Another key advantage of purchasing a new industrial mixer is the warranty and customer support that typically come with it. Most reputable manufacturers provide warranties that cover any potential defects or issues that may arise during the initial period of use. Additionally, they offer reliable customer support to address any concerns or queries you may have, ensuring a smooth and hassle-free experience.

Newer industrial mixers often incorporate the latest technological advancements, which can significantly enhance their performance and efficiency. From improved motor power to advanced control systems, these technological upgrades can have a direct impact on the quality and consistency of your mixing processes. By investing in a new mixer, you can take advantage of these innovations and stay ahead in your industry.

When purchasing a new industrial mixer, you have the opportunity to customize it according to your specific requirements. Whether it’s choosing the capacity, speed settings, or additional features, customization allows you to tailor the mixer to perfectly fit your production needs. This level of flexibility is often not possible when buying a used mixer, where you have limited control over its specifications.

While the upfront cost of a new industrial mixer may (this is not always the case) be higher than that of a used one, it’s important to consider the long-term cost savings. Sometimes mixers are priced higher than what you actually need to spend because they were purchased for the previous users specifications. Your specifications may allow for significant cost savings on ordering new. For a good comparison, go to the used sites, then see our price guide below. New mixers are generally more energy-efficient, resulting in lower utility bills over time. Additionally, their reliability reduces the need for frequent repairs or replacements, saving you money on maintenance and downtime expenses.

Mixers are widely used to blend, disperse, and homogenize materials in various industries, including chemical, pharmaceutical, food and beverage, cosmetics, and wastewater treatment. They ensure uniform consistency, improve reaction efficiency, and enhance product quality. Mixers are suitable for liquids, powders, and semi-solids, supporting stable processing and efficient production in industrial manufacturing systems.

Concrete drum mixers are used in the construction industry and play a vital role in making concrete. Cement is used for foundations, bridges, airports, slabs, dams, railroads, and walls. These mixers are efficient in producing the exact amount of material to complete a task. The raw materials are fed into the feeder and the concrete gets mixed. When the materials are thoroughly mixed together, workers collect the finished product on the other end.

Industrial mixers are widely used in the chemical manufacturing industries. Chemical applications include chemical make-up, solids suspension, pH control, additive blending, wastewater treatment, temperature control, emulsification, gas dispersion and dynamic inline blending. Hi-Shear industrial mixers are well-suited for applications involving paints, coatings, pesticides, and adhesives. They are also appropriate for ethanol and biofuel production. High shear mixers are crucial in creating pesticides for example by mixing insoluble active ingredients in water or oil-based solutions with thickeners, anti-freeze, anti-forming agents, and additives to help create the base formula.

Industrial mixers play a pivotal role in one of the most demanding industries in the world, the mining industry. Applications include, but are not limited to gold leach, CIL & CIP, cyanide destruction, pipeline slurry storage, attrition scrubbing, solvent extraction, conditioning tank mixing, storage and mining wastewater. In applications, such as cyanide destruction an industrial mixer effectively disperses the gas and blends agents together to make sure the cyanide is destroyed. Cyanide is extremely toxic and can be extremely harmful to the environment and public health if not destroyed or contained. Industrial mixers and other tools help prevent the possibility of cyanide spills that have resulted in killing large groups of fish, contaminated water supplies and harmed agricultural lands in the past.

Industrial Mixers are essential in the manufacturing process of paints and resins. Matching a color profile with the proper pigment is a necessity. Industrial mixers make sure the product is properly mixed and controlled, so the right color and consistency is achieved. They also mix additives into the product that increase the paint finish’s durability. Agitators, high shear mixers, drum mixers and paddle mixers are commonly used to mix paint in industrial processes.

Industrial Mixers are used in the pulp and paper industry to remove natural lignin by breaking down the cellulose fibers. At the end of the mixing process the heterogenous mix is a more consistent, homogenous mixture. Producing a thoroughly mixed chemical mixture to remove the lignin makes industrial mixers pivotal to the pulp and paper industry. Industrial mixers are also significantly important in pulp stock chest mixing, Pulp digester mixing, Kraft recovery process, mechanical pulp and thermo-mechanical pulp blending tanks, latency chests, and wastewater treatment processes.

Industrial mixers are heavily involved in the oil and gas industry. Applications include oil drilling, crude oil tank mixing, asphalt mixing, and creating fuel additives. When drilling for oil a drilling fluid is used to keep the drill bit clean and to keep it from overheating. Industrial mixers play a crucial role in the drilling process by premixing this drilling fluid consisting of a stabilized water-in-oil mixture in a heavily agitated tank. Not only are industrial mixers involved in the early stages of oil production they are involved in the later stages as well, mixing the additives into the final product.

Industrial equipment is known for high power consumption, contributing to large carbon footprints. However, modern commercial mixers have energy-efficient innovative features that reduce carbon emissions. These features are worth considering when purchasing an industrial mixer to meet the government’s industrial legislation on power consumption and carbon emission. This would result in carbon credit and cost reduction.

Commercial mixers are large vessels carrying lots of powder or liquid mix. The size of the product determines the vessel’s capacity. Larger mixing vessel capacities are productive but could also mean extensive downtime due to more time spent emptying, loading, and cleaning. Other factors to consider when determining a suitable vessel’s capacity are the heigh and volume of the batch and the vessel’s diameter.

The batch size is one of the first things you want to consider on an industrial mixer since it determines the production quality. Continuous production provides higher capacity with fewer cleaning and release cycles. It is suitable for companies involved in large-scale production. On the other hand, batch production does the mixing in the intermediate bulk containers, providing higher product quality and better tracing for exceptional and diverse products.

The industrial mixer should be compatible with the liquid or ingredients. The company should consider the liquid viscosity before adding other ingredients like powder. Some frequent liquid behaviors worth examining include:

Newtonian fluids: Since they contain water, hydrocarbons, oil, and minerals, they maintain their consistency regardless of the mixing speed.

Thixotropic fluids: These fluids can lose their viscosity with increased mixing speed. They include inks, soaps, tars, glue, and peanut butter.

Pseudoplastic fluids: They include latex, paints, and cream, and their viscosity increases with high mixing speed.

Dilatant fluids: Their viscosity rises when the shear rate increase.

The industrial mixer’s mixing time is essential because it affects the blender’s life cycle and power consumption. Generally, preparing the blender takes 2 hours, and filling the mixture takes 3 hours. However, mixing time depends on the blender’s efficiency and material properties. Therefore, the company that wants to save on production costs should consider the blender’s efficiency and mixing time.

The machine’s cleaning time is part of the production time. Most industrial mixers require quick ingredient change and thorough cleaning to avoid contamination before different ingredients are loaded. Debris from the blending and mixing process could stick on paddles, bearings, and sidewalls, hence the need to choose a blender that is easy to clean to save time.

We have a complete factory production, quality supervision and delivery.

Our main product including all kinds of forged stainless steel flanges, Stainless steel valves, Stainless steel pipe fittings for both food grade and industrial application.

Xingsheng have more than 10 years export experience, Our main export market including: United states, South America, Australia, South east Asia and Europe. Base on our strict quality control system and quality products. We have export more and more products world wide.

A: A pump is a mechanical device designed to move fluids, such as liquids or gases, from one place to another.

A: Pumps work by creating a flow of fluid through mechanical action, often using impellers, pistons, or diaphragms to generate pressure and movement.

A: Common types include centrifugal pumps, positive displacement pumps, diaphragm pumps, and reciprocating pumps.

A: A centrifugal pump uses a rotating impeller to create a flow of fluid by increasing its kinetic energy.

A: Consider factors such as impeller design, suction and discharge ports, sealing mechanisms, pressure and temperature ratings, and materials of construction.

A: Centrifugal pumps are widely used in water supply, irrigation, and various industrial processes.

A: In the oil and gas industry, pumps are used for storing, transporting, and transferring oil and gas.

A: Pumps play a key role in water treatment plants by facilitating the movement of water through various treatment stages.

A: Yes, certain pumps are designed to be self-priming, reducing the need for external priming before operation.

A: Pumps are constructed from materials compatible with the pumped fluid, often including stainless steel, cast iron, or other alloys.

A: Yes, pumps typically require regular maintenance to ensure optimal performance, including checking seals, lubrication, and inspecting components.

A: Yes, some pumps allow variable speed control, providing flexibility in adjusting flow rates based on demand.

A: Safety features may include overload protection mechanisms and emergency stop features for quick cessation of operations.

A: Consider the specific requirements of your application, including fluid properties, flow rates, pressure conditions, and industry standards, to select the most suitable pump type.

A: Common types include batch mixers, continuous mixers, and agitators, each designed for specific mixing applications.

A: Batch mixers blend a specific quantity of materials in a single batch, offering controlled mixing and a discharge mechanism for batch removal.

A: Batch mixers process a specific quantity at a time, while continuous mixers blend materials as they pass through the system for uninterrupted production.

A: Mixers find applications in the food industry for sauces and dough, pharmaceuticals for powder and granule mixing, chemical processing for formulation blending, and cosmetics manufacturing for uniform product mixing.

A: Mixers can be powered by electric motors or mechanical systems, with some allowing variable speed control for flexibility in mixing intensity.

A: Mixers are constructed from materials compatible with the mixed substances, with some designed for easy cleaning to prevent cross-contamination.

A: Mixers may have features for ease of cleaning and wear resistance, and they generally require maintenance to ensure optimal performance and prolonged equipment life.

A: Safety features may include overload protection mechanisms and emergency stop features for quick cessation of operations.

Add: No.51 Wutong Road, Binhai Industry Zone, Longwan District, Wenzhou City, Zhejiang Province, 325025, China

Tel: +86-577-89690837

+8613375872366

Email: info@seasomtech.com

Website: https://www.seasomtech.com